Home » Products » Make up and Break out Tools » Hydraulic Make and Break Unit » Hydraulic Make and Break Unit (360º rotation)

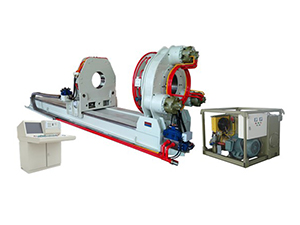

Hydraulic Make and Break Unit (360º rotation)

Features

- This make and break unit adopts cylinder clamping and the continuous rotation is driven by hydraulic motor. It clamps once during one make-up process, leaving one gripping mark on the surface of the pipe.

- Automatic control of stepless speed change: The displacement of the hydraulic system is automatically controlled by the computer according to the set torque value. With the increase of the torque value, the displacement of the system will automatically track down, and when the torque value decreases, the displacement of the system will automatically track up, so as to achieve fast make-up, slow screwing torque.

- High precision synchronous motor ensures the cylinders of completely synchronized clamping.

- Auxiliary feeder is available for the make-up and break-out of pipes with size of12 M, ø406.

- Auxiliary feeder comes with 4 sets of axial spinning roller and a central height adjusting device.

- The electrical control system and hydraulic system are combined to ensure stepless adjustment of the rotary speed of the power tong within 0.5r/min~8r/min.

- Dies of 2⅞″~22″ can be conveniently replaced though the pin on the jaw plate

- This make and break unit allows for the make-up and break-out operations of eccentric workpieces, with a maximum eccentric distance of 100mm.

- The backup tong is designed as floating type to ensure that the pipe is in free floating state during the make and break operation.

- Two measuring units are optional in N·m or ft·lbs.

- This make and break unit has functions of automatic control of make-up and break-out and automatic alarm in case of over-torque.

- High precision, high rotation speed optical-electricity encoder is adopted to record the screwing rounds.

- Based on the operation requirements, it allows the setting and recording of the make-up parameters, and pipe and coupling parameters.

- This make and out unit is ideal for the make-up operations of special threaded connections like. And it also supports the measuring and recording of make-up torque, shouldering torque, the ratio of make-up torque and shouldering torque.

- The data during the make-up process can be recorded on a disk for future review.

Technical Parameters

| Model | CZJ340-70 | CZJ400-100 | CZJ500-120 | CZJ762-150 | CZJ920-160 | ||

| Applicable pipe diameter | mm | Φ60.3~Φ340 | Φ60.3~Φ406 | Φ177.8~Φ508 | Φ340~Φ762 | Φ340~Φ920 | |

| in | 2-3/8″~13-3/8″ | 2-3/8″~16″ | 7″~20″ | 13-3/8″~30″ | 13-3/8″~36″ | ||

| Max. torque | kN.m | 70 | 100 | 120 | 150 | 160 | |

| ft.lbs | 51664 | 73806 | 88567 | 110701 | 118081 | ||

| Rotatory speed | rpm | High Gear: 15 Low Gear: 5 | 0.5-6 | 0.5-5 | 0.5-4 | 0.5-4 | |

| Center height | mm | 1150 | 1150 | 1220 | 1250 | 1600 | |

| Max diameter | mm | Φ420 | Φ480 | Φ580 | Φ850 | Φ1020 | |

| Motor Power | kW | 37 | 37 | 45 | 55 | 55 | |

| Max. flow | Lpm | 160 | 160 | 250 | 250 | 250 | |

| Overall Size(L*W*H) | Make and break unit | mm | 5300*1500*1730 | 6000*1430*1900 | 6000*1600*2100 | 4200*2018×2689 | 4200×2150×3200 |

| HPU | mm | 1750*1080*1140 | 1750*1380*1200 | 1800*1400*1300 | 1800*1400*1300 | ||

| Console | mm | 950*1020*1160 | |||||

| Weight(approximately) | kg | 7700 | 9800 | 12000 | 13500 | 15000 | |

Inquiry Form

English

English Русский

Русский Español

Español