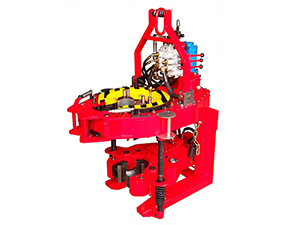

No-marking Hydraulic Power Tong

No-marking hydraulic power tong is specially designed to break out the coupling of coated tubing/casing, FRP tubing/casing, plastic tubing/casing, and anticorrosion tubing/casing like VAM TOP, BGT1, FOX, 3SB, etc. It is a global difficult problem in the manufacture of oil production equipment to require no damage to tubing/casing surface, and researchers at home and abroad still can not solve this problem. After more than ten years of research, the researchers of our company solved this problem, overcoming hardness with softness. The synthetic fiber with high strength, high friction coefficient and high elasticity is adopted and molded by high-density braided. The hardness of all materials is lower than HS80 (Shore hardness). This realizes no gripping marking on the surface of coated tubing/casing, FRP tubing/casing and plastic tubing/casing.

Features

- No-marking hydraulic power tong is suitable for VAM TOP, BGT1, FOX, 3SB and other types of tubing and casing of common materials with general or special threads. It is especially ideal for tubing and casing with inner coating.

- The clamping force is twice as high as that of the ordinary hydraulic power tongs.

- Providing coverage up to 300 degrees, even if the clamping force is twice as high, the pipe body will not be deformed.

- The three-jaw-plate clamping structure ensures slip-free operation and no deformation.

- The friction coefficient of anti-corrosion coating outside the tube and the cleaning degree of the tube surface will affect the make-up torque. Safety door adopts automatic interlocking for safety and reliability.

- The floating connection of the back-up tong allows for precise measuring of the make-up torque.

- The automatic transmission system enables stepless speed change, allowing make-up at high speed and torqueing at low speed. This not only improves the working efficiency, but also conforms to the API specification, avoiding over-torque of the pipe with shouldering thread.

Technical Parameters

| Model | YQ89-16W | YQ140-30W | YQ180-30W | YQ245-35W | |

| Applicable pipe diameter | 2-3/8"~3-1/2" | 2-7/8"~5-1/2"+157 | 3-1/2"~7" | 3-1/2"~9-5/8" | |

| Output torque | High gear | 4400ft·lb 6000 N·m | 5900 ft·lb 8000 N·m | 8100ft·lb 11000 N·m | 8800ft·lb 12000 N·m |

| Low gear | 11800ft·lb 16000 N·m | 22110ft·lb 30000 N·m | 22110 ft·lb 30000 N·m | 25800 ft·lb 35000 N·m | |

| Speed | High gear | 26RPM | 18RPM | 12RPM | 10RPM |

| Low gear | 10RPM | 5 RPM | 4 RPM | 2 RPM | |

| Rated flow | 2000PSI 40GPM /14 MPa 120 LPM | ||||

| Overall size (L×W×H) | 43.3"×29.5"×33.5" 1100×750×850mm | 57.5"×35"×69.3" 1460×880×1760mm | 61"×39"×69" 1550×1000×1760m | 64"×42.5"×72" 1630×1080×1830mm | |

| Weight | 1763 lb / 800 kg | 2976 lb /1350kg | 3196 lb / 1450 kg | 3520 lb / 1600 kg | |

English

English Русский

Русский Español

Español