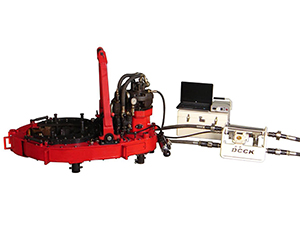

Home » Products » Make up and Break out Tools » Torque Control System » NKY-3G Torque Control System

NKY-3G Torque Control System

NKY-3G torque control system is updated based on NKY-C8 and NKY-Y/T/Z series torque controllers. This new generation product owns two patented technologies, with good versality, high reliability, low failure rate and easy operation. This torque controller is designed to meet the needs of domestic and foreign users, featuring user-friendly operation.

Features

- Good versality: this torque control system can be used together with any domestic and abroad hydraulic power tongs.

- This torque control system is suitable for make-up operations of special threaded connection such as VAM TOP, BGT1, FOX, 3SB, 13Cr, etc. It supports the measuring and recording of make-up torque, shouldering torque, and the ratio of make-up torque to shouldering torque.

- The torque control system has a solid structure to be anti-impact, anti-corrosion and adaptable to the harsh working environment.

- The enclosed case structure is water proof and anti-shock.

- Large displacement dump valve features fast response to ensure no over-torquing during the make-up.

- Easy transportation: when transporting the hydraulic power tongs, this torque controller is easy to assemble and disassemble.

- Manual and automatic storage are optional.

- 12 bits high precision analog A/D conversion module ensures high sampling rate.

- High precision, high rotation speed optical-electricity encoder is adopted to record the make-up rounds.

- The torque control is equipped with a fast dump valve for automatic control of make-up torque.

- Based on the operation requirements, the make-up parameters, including pipe and coupling parameters, ma/min torque, etc.

- Displaying, controlling and recording of make-up parameters are available. The data can be recorded on a disk for future review.

- Multiple printing choice: one or eight graphics can be printed on A4 paper.

- Reliable hardware and software provide complete function, easy operation, reliable running and convenient maintenance, making it suitable for harsh oilfield operations.

- The coupling of the pipe adopts 1" and 1¼"NPT threaded connection.

Technical Parameters

-

- Power requirements: 220V AC ±15%, 50 to 60Hz

- Power supply: 24V DC

- Power consumption: 80W

- Torque range: can be set

- Response time: output control: <0.5ms;

hydraulic dump valve: 10-20ms - Rated temperature: -15°C to +65°C

- Torque accuracy: ≤0.5%

-

- Control accuracy: ≤2.5%

- Unloading relief: 120L/min

- Protection rating: IP 67

- Humidity range: 10% to 80% RH (non-condensing)

- Overall size: torque control system: 550×360×300mm

- Accessories box: 550×430×300mm

- Weight (Approx.): 56kg

Inquiry Form

English

English Русский

Русский Español

Español